Vacuum Pumps: Types and Applications

AZMEC is a leading company in the global production and supply of vacuum pumps and liquid ring compressors. But what are vacuum pumps? It is certainly worth exploring the characteristics of these machines, defining their main types and applications.

In the industrial field, vacuum is an essential condition for a wide range of processes, from the manufacture of semiconductors to medical applications, from the automotive industry to the production of materials such as glass, plastic, and rubber. In this article, we will explore the advanced types of vacuum pumps offered by AZMEC and their multiple industrial applications. Happy reading!

Features of Vacuum Pumps

Vacuum pumps are mechanical devices used to create and maintain a vacuum, i.e., a condition of pressure lower than atmospheric pressure. This type of compressor moves a gaseous fluid from a lower to a higher pressure.

Unlike a true compressor, however, the vacuum pump operates at variable suction pressure and constant discharge pressure. AZMEC offers a wide range of vacuum pump models, each designed to meet specific needs and ensure reliable performance.

Types of Vacuum Pumps

The types of vacuum pumps on the market are distinguished by the pressure ranges they cover and the applications they can be used for. Among the various types of vacuum pumps, it is possible to distinguish:

– Rotary pumps: This category includes vane pumps and rotary piston pumps, ideal for generating medium vacuum, widely used in the automotive, food, and pharmaceutical sectors.

– Diffusion pumps: Designed to create high-pressure vacuums, as required in the manufacture of some semiconductors.

– Turbo-molecular pumps: Used for applications at even higher pressures, such as in electron microscopy and scientific research.

– Getter and ionic pumps: Mainly used in scientific research.

– Cryogenic pumps: Use the process of condensation and freezing to reduce the number of free gaseous molecules and thus the pressure.

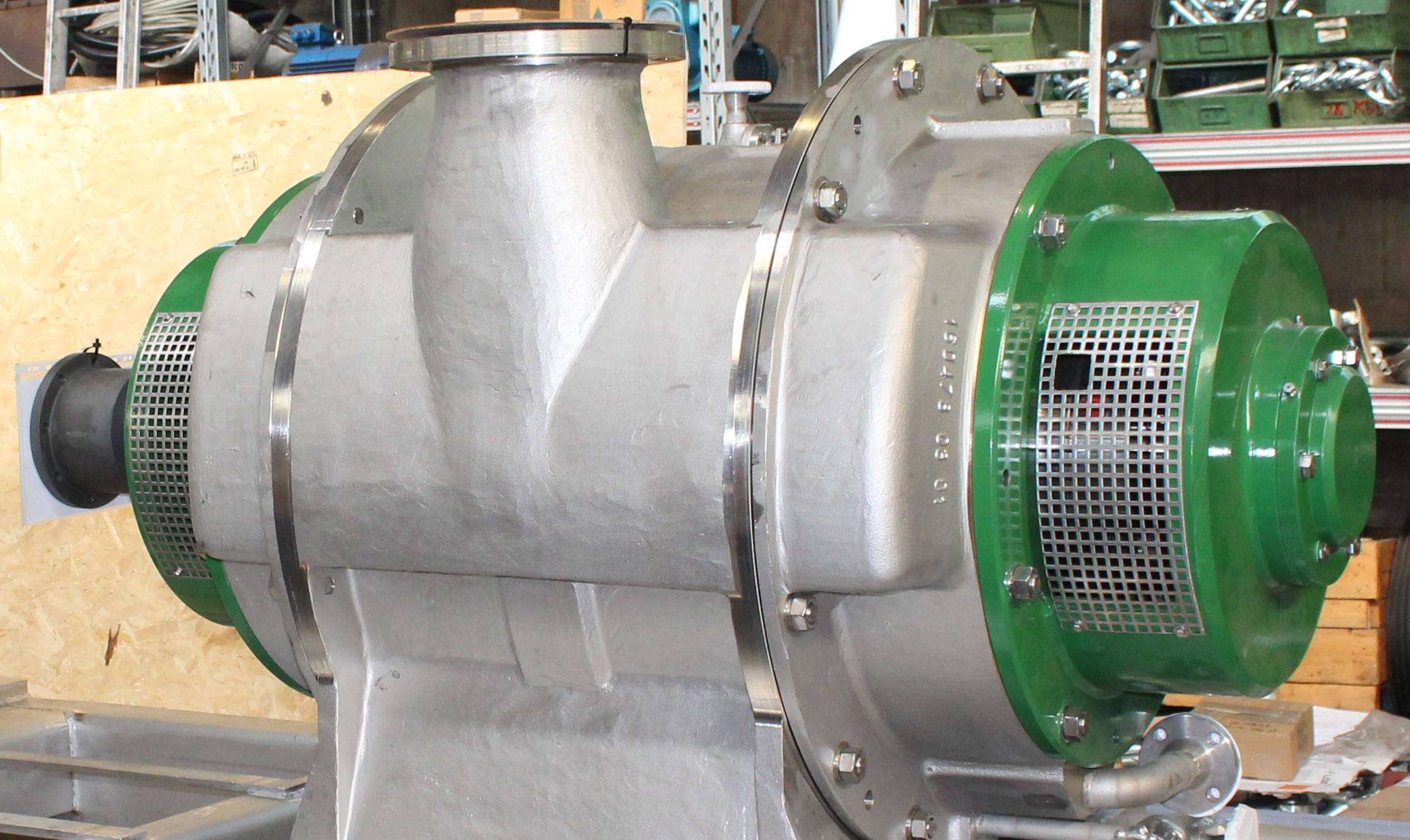

The types of vacuum pumps offered by AZMEC vary depending on the specific needs of customers. Our company offers several models of vacuum pumps, distinguished by line and model, having different characteristics to ensure application efficiency. The AL, ALZ, ALBV, AL-B4, and AL-BC series, for example, ensure reliability and efficiency through the use of distributors with large passages, while the ALCZ series uses flat distributor disks and exhaust diffusers with valves to avoid overpressures.

Applications of Vacuum Pumps

Vacuum pumps are fundamental devices in virtually all industrial sectors, including the food, pharmaceutical, steel, petrochemical, textile, tanning industries, as well as in the paper, cellulose, cement, and plastics industries.Here are some concrete applications of these versatile devices:

– Manufacture of semiconductors

– Medical processes requiring suction and production of some types of drugs

– Operation of brakes in the automotive field

– Production of materials such as glass, plastic, and rubber, particularly for making light bulbs and cathode tubes

– Distillation, evaporation, crystallization, and filtration of some chemicals

– Production of vacuum-packed foods and dairy processing

– Electron microscopy and scientific research

Choosing the right pump is a fundamental step to ensure the success of your industrial operations. The specific needs of the application, operating conditions, and vacuum requirements are all crucial factors to consider.

Given the centrality of vacuum pumps in a wide range of industrial sectors and technological applications, it is important to rely on a competent and experienced company in the production of these devices, in order to maximize results and minimize the energy consumption of your company.

Conclusion

This is where AZMEC comes in, which with decades of experience in the field, will be able to advise and create the ideal vacuum pumps for all the needs of your company. Trust the experts: we are ready to put all our knowledge and expertise at your complete disposal, to provide you with customized and high-quality solutions. Visit our website for more information on the specifications of our products.

Contact us to schedule a consultation and define the action plan aimed at meeting your needs! We are ready to accompany you in every operational phase, from initial consultation to production, supply, and installation of devices, ensuring complete support throughout the journey.