The AL/2000 Series: A Detailed Analysis

With over 60 years of experience in the industry, AZMEC is a leading company in the global production and supply of industrial machinery. Specializing in the manufacture of vacuum pumps and liquid ring compressors, AZMEC offers high-quality solutions for a wide range of industrial sectors: from the petrochemical to the textile industry, from pharmaceutical to food industry.

Azmec’s focus on the quality of its products is reflected in the certified materials used in the production of vacuum pumps and liquid ring compressors. These materials ensure not only productive efficiency and operational safety, but also significant reductions in energy consumption and costs.

The types of vacuum pumps offered by AZMEC vary, each designed to adapt to the specific needs of our customers. Depending on the model used, reliability and efficiency of operation are ensured by different features.

The AL, ALZ, ALBV, AL-B4, and AL-BC series, for example, ensure reliability and efficiency through the use of distributors with large passages. On the other hand, the ALCZ series uses flat distributor disks and discharge diffusers with valves to avoid overpressure even under heavy working conditions.

AZMEC’s vacuum pumps are designed to ensure smooth and continuous operation even in the presence of dirty water, impurities, overloads, and poor maintenance. Thanks to their robust design and choice of materials, these pumps can operate under harsh conditions and provide reliable performance over time. The high quality of our products and machinery is also guaranteed by their oversized dimensions, rather wide passage sections, low rotation speeds, careful machining of the machines, and the choice of high-level materials.

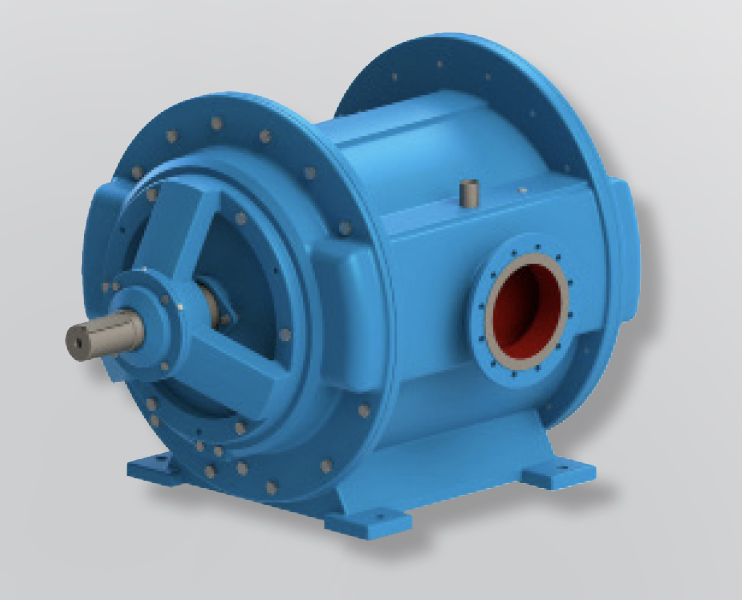

All these characteristics contribute to achieving our goal: customer satisfaction in every need. In this article, we dedicate ourselves to analyzing the AL/2000 series of vacuum pumps, providing you with all the fundamental details of these machines.

Construction Materials of the AL/2000 Series

The products made by AZMEC are the result of a meticulous development process, reflecting the company’s commitment to researching innovative, customized, and optimized solutions for every customer. The AL/2000 series, made with high-quality materials and designed thanks to long-standing experience in the industry, reaffirms the company’s dedication to providing machinery of excellent performance and reliability.

In the creation of the AL/2000 series of vacuum pumps, AZMEC has relied on highly performing materials that ensure the solidity and reliability of the product in any operational situation. The main materials used for their construction include cast iron, carbon steel, stainless steel, ceramic-coated steel, and a combination of two or more materials. Let’s take a closer look:

– Cast iron is a ferrous alloy renowned for its excellent mechanical and thermal resistance. This material gives the pumps robustness, rigidity, and corrosion resistance, ensuring long-lasting operation.

– Carbon steel is the best option where greater mechanical resistance is required, thanks to the ability to harden this material to increase its hardness.

– Stainless steel is the ideal choice for conditions requiring high resistance to corrosion and erosion, mixed with excellent temperature resistance. These qualities are obtained thanks to the presence of chromium and nickel. For its resistance to corrosive agents, the AL/2000 pumps made with stainless steel are ideal for the chemical and food sectors.

– Ceramic-coated steel provides the pumps with particular resistance not only to corrosion but also to abrasion, allowing them to operate in very aggressive environments.

– Some models, instead, foresee the use of two or more materials, allowing the machinery to be more adaptable to specific usage conditions, ensuring excellent performance depending on the needs.

The materials just analyzed are carefully selected and tested to ensure excellent resistance and durability over time, which, coupled with reduced energy consumption, has led countless companies to rely on our services.

Technical Details

The AL/2000 series is constructed with 2 horizontal ports, one for suction and one for discharge, and each model in the series has specific flow characteristics, which can vary from 180 m3/h to 12,500 m3/h. Regarding sealing, it is possible to identify different solutions, from the classic packing seal to the more modern simple or double mechanical seal.

Thanks to their versatility, the pumps and compressors of the AL/2000 series prove to be highly performing solutions capable of meeting the needs of a wide range of industrial sectors: consider the pharmaceutical industry, the steel industry, but also the food and petrochemical industries.

With our consolidated experience in the design and production of industrial machinery, AZMEC is able to provide tailor-made products capable of meeting the specific needs of each customer and each environment. Our team of engineers, composed of highly qualified professionals, is ready to provide you with all the necessary technical support to ensure your maximum satisfaction.

Aware of the importance of fully understanding your needs and goals, we are ready to offer you customized and innovative solutions. Contact us for more information, we will be pleased to work together with you to offer you the ideal solutions for your needs. Your satisfaction is our priority, and we are ready to put our experience and expertise at your disposal.